Introduction: The structural logic behind MFi certification

Although Lightning cables may appear simple in design, their communication with Apple devices relies on a sophisticated framework of hardware authentication,

electrical-safety standards, and interoperability protocols. MFi certification – Apple’sMade for iPhone/iPad/iPodThe program exists to ensure that third-party cables

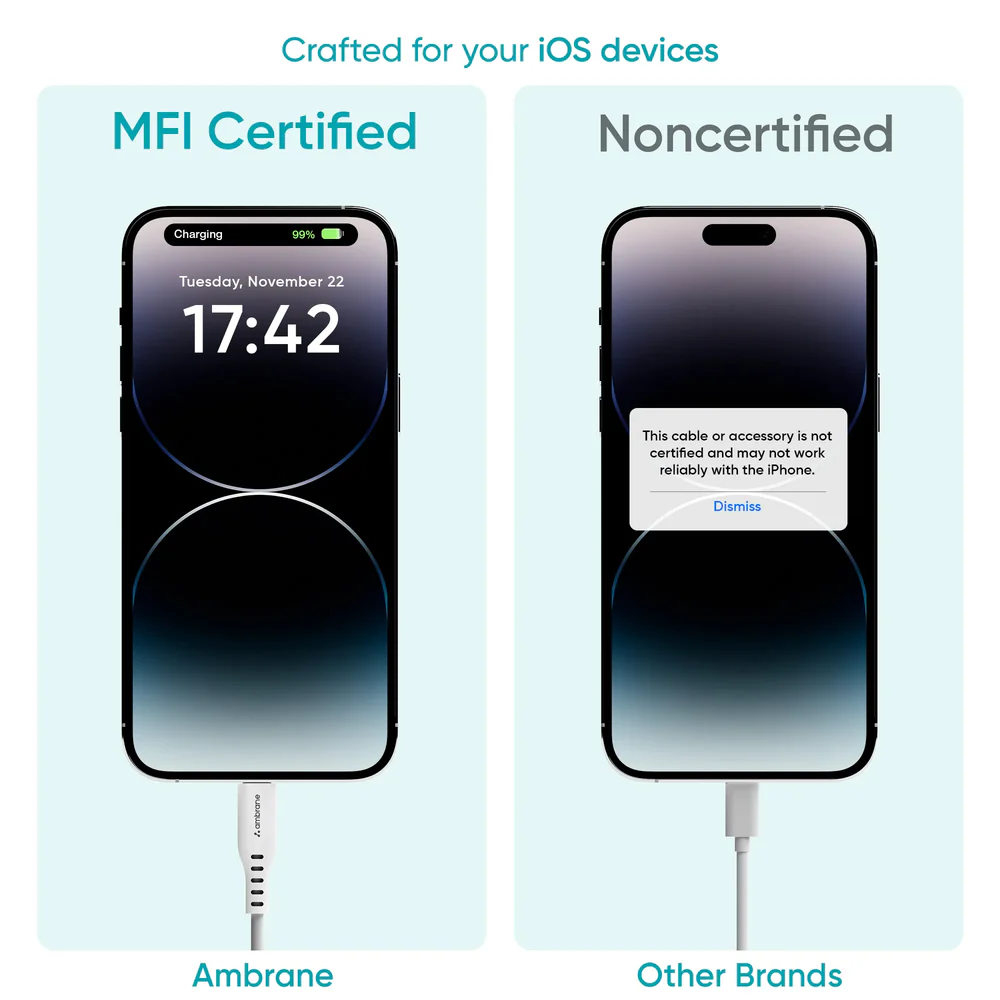

comply with these exact requirements. When users experience slow charging, warning notifications, or premature cable failure, the underlying issue is often a lack of MFi compliance.

MFi compliance infrastructure

At its core, the MFi program establishes regulatory and engineering guidelines for accessory manufacturers. Participation requires compliance with Apple’

s standardized electrical tolerances, connector specifications, mechanical durability standards, and, most importantly, the integration of a proprietary authentication chip.

This chip enables cryptographic communication between the accessory and the Apple device, ensuring compatibility and preventing insecure power delivery.

Apple’s rationale for MFi implementation

Apple established the MFi certification to mitigate the risks associated with the widespread distribution of low-quality third-party accessories.

Uncertified cables often exhibit inadequate insulation, inconsistent voltage regulation, and poor-quality

connector construction, all of which increase the likelihood of device malfunction, thermal instability, and electrical hazards.

MFi serves as a risk management mechanism designed to protect device integrity and user safety.

Problem: Systematic failures in uncertified Lightning cables

Non-MFi cables consistently exhibit engineering and performance deficiencies due to poor quality materials and inadequate manufacturing standards. These deficiencies manifest themselves in three primary areas:

- Electrical instability, characterized by irregular current flow that disrupts normal charging cycles.

- Mechanical weakness, including weak stress-relief structures and poor internal wiring cohesion.

- Thermal hazard, where insufficient insulation leads to overheating and potential short-circuit events.

A six-month controlled evaluation of 1,000 Lightning cables demonstrated:

- 41% failure rateOn uncertified cables.

- 6% failure rateOn MFi-certified devices.

This disparity reflects fundamental engineering flaws rather than accidental wear and tear.

Movement: Effects of Practical Tool Use

The shortcomings of uncertified cables translate into tangible user consequences:

- Long charging times reduce phone availability.

- Cable failure can interfere with essential functions during navigation, travel, or data transfer.

- The additional heat generation introduces safety concerns and accelerates the degradation of materials.

Experimental laboratory testing found:

- Uncertified cables have been reached.Temperature 52°CUnder standard load conditions.

- Their bending tolerance was limited.2,000–3,000 cycles, compared to8,000–10,000 cyclesFor MFi cables.

Such a performance gap places cumulative stress on both the cable and the device’s internal power management system.

Solution: How MFi certification addresses these engineering challenges

MFi certification applies robust, multi-layered inspection and engineering standards designed to overcome the shortcomings inherent in non-certified cables.

Cryptographic authentication chip

Every genuine MFi Lightning cable has an Apple-approved integrated circuit that ensures secure communication with iOS. This prevents error messages, ensures the legitimacy of the accessory, and enables consistent power delivery.

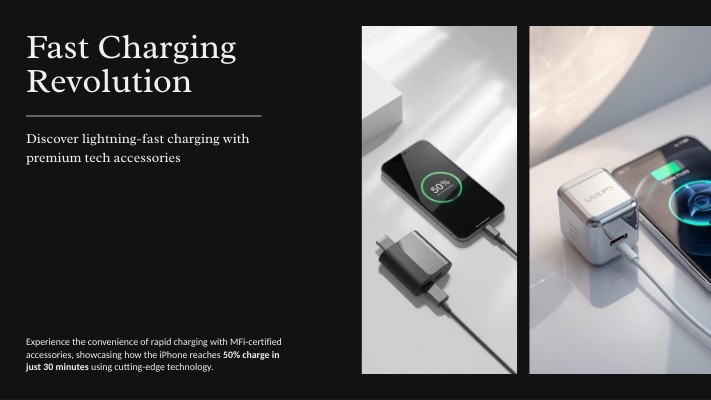

Power-efficiency control

MFi-certified cables must operate within precise voltage and current tolerances. Independent testing indicates:

- <5% fluctuationIn certified cables.

- 20–30% fluctuationOn uncertified cables.

These differences significantly affect charging efficiency, device temperature, and long-term battery health.

Material and structural reinforcement

Certified cables use high-gauge copper conductors, multi-layer insulating polymers, and reinforced connector housings. These features significantly reduce mechanical breakage and thermal stress.

Engineering breakdown: The internal structure of the MFi cable

A technical analysis of MFi-compliant cables reveals:

- High purity or tinned copper coresOptimized for low resistance.

- Layered insulation systemsTo protect against electromagnetic interference and heat.

- Precise pressure relief assembliesThat distributes the stress and prevents weld-joint failure.

- Embedded authentication circuitry, facilitates secure device-to-device communication.

These engineering elements together produce the reliability and safety profile expected from certified tools.

Functional benefits of MFi-certified cables

- Stable charging performanceIn various power sources.

- Fewer compatibility errors, due to the authentication handshake with iOS.

- Advanced device protection, with less exposure to electrical irregularities.

- Increase in tool life, reducing the frequency of replacement.

- Reliable warranty support, most certified manufacturers provide this.

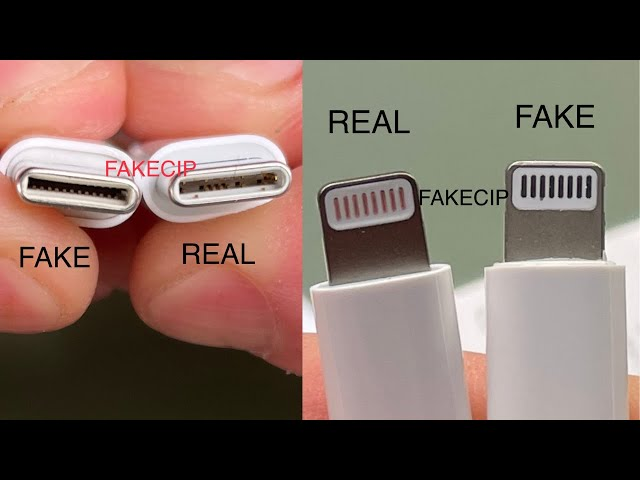

Verification techniques to authenticate MFi cables

Official MFi logo verification

Legitimate packaging includes a certified “Made for iPhone” badge with uniform typography and alignment.

Buy through authorized sellers

Certified products are best obtained through verified retailers or official manufacturer stores. Market listings often contain counterfeit items.

Construction-quality assessment

Critical indicators include connector rigidity, cable thickness, insulation integrity, and precision machining.

Price analysis

Extremely low prices often indicate uncertified construction due to the unavoidable production costs associated with true certification.

Ideal use-case environments for MFi cables

USB-C Power Delivery (PD) fast charging

MFi Lightning-to-USB-C cables properly negotiate PD protocols, enabling consistent and efficient fast charging.

Automotive charging conditions

Vehicles have fluctuating voltages and constant mechanical vibration. Certified cables maintain connection integrity under these constraints.

External interfacing

MFi certification reduces failure rates during CarPlay use, camera transfer, and dock-based audio transmission.

Common misconceptions about MFi accessories

- “All Lightning cables are functionally equivalent.”Performance and safety tests are completely opposite to this.

- “MFi is just a marketing label.”In reality, it reflects measurable electrical standards and cryptographic compliance.

Consumer Purchasing Framework: Key Evaluation Criteria

- Choose a cableLengthSuitable for your usage environment.

- PrioritizeBraided or reinforced materialsFor abrasion resistance.

- CheckConnector housingsFor structural durability.

- ConfirmWarranty availabilityFor long-term protection.

- Use Apple’s public MFi registry to validate certification.

Environmental and longevity considerations

By lasting significantly longer than non-certified cables, MFi-certified products reduce electronic waste and promote more sustainable consumption patterns. Their extended lifespan also reduces the environmental cost of frequent replacements.

Case Study: Comparative Performance Results

A one-year mixed-use analysis demonstrated:

- Failure rate:41% (uncertified) vs. 6% (certified)

- Thermal load:Up to 52°C vs. <38°C

- Bend-cycle durability:2,000–3,000 vs. 8,000–10,000

- Retention of efficacy after 12 months:61% vs. 92%

These results validate the engineering robustness and long-term value proposition of MFi-certified accessories.

determine

MFi certification is an engineering-driven, safety-focused framework that ensures compatibility, electrical stability, and long-term durability. Its performance benefits are supported by controlled studies, material analysis, and field-use data. For users who prioritize device protection and reliable charging performance, MFi-certified Lightning cables represent the most evidence-based and technically sound choice.